.png)

High-Speed Operation

Automation and Efficiency

Seamless Software Integration

Fiber Laser Machine

Fiber laser machines are an excellent choice for businesses looking for high-speed, precise, and cost-effective solutions for cutting, engraving, and marking metals and other materials. They offer a combination of low maintenance, high efficiency, and versatility, making them suitable for a wide range of applications across different industries.

SG Laser provides high-performance cutting and engraving tool that uses a fiber-optic laser to deliver precise, fast, and clean results on a variety of materials. Known for its energy efficiency, low maintenance, and exceptional accuracy, it offers superior cutting speed and detail compared to traditional methods. Fiber lasers are ideal for applications in industries like manufacturing, automotive, aerospace, and signage, providing reliable, long-lasting performance for intricate designs and high-volume production.

.png)

-

Fiber laser machines generally have lower operating costs compared to other laser systems (like CO2 lasers), as they require less maintenance and have higher power efficiency.

-

Features such as automatic loading and unloading systems, to allow our clients to have a full line of automation and reduce manual labour.

-

CNC & CAD Integration: Works with most design software for automated cutting.

-

User-Friendly Interfaces: Many machines come with touchscreen controls and presets.

-

Industry 4.0 Compatibility: Some models integrate with smart manufacturing systems.

Cost Effective

Versatile Material Handling

-

Advanced laser technology ensures clean, accurate, and consistent cuts, even on intricate designs or thick steel materials.

-

Fiber laser cutting machines are particularly well-suited for cutting metals of varying thicknesses, from thin sheets to thicker materials (up to several millimeters thick, depending on the machine's power).

-

The thickness that can be cut depends on the power of the fiber laser and the type of material.

-

Fiber laser machines are known for their fast processing speeds, which makes them ideal for high-volume manufacturing or batch processing.

-

The high intensity and efficiency of the laser allow for rapid cutting and reduced processing time compared to traditional methods like C02.

Energy & Performance Efficiency

-

Fiber lasers are more energy-efficient compared to traditional CO2 lasers. This means lower operating costs, especially for high-volume cutting and engraving tasks.

-

Fiber lasers also have a longer lifespan (typically over 100,000 hours), and they require less maintenance.

-

Designed with energy-saving technology to reduce power consumption while maintaining high performance.

Energy & Performance Efficiency

PRECISION LASER CUTTING MACHINERIES

Laser Cutting Machinery, being our very first core business, our commitment to quality is matched by exceptional after-sales service, ensuring our clients receive the support they need to maximize productivity and achieve success.

Backed by a team of experienced professionals, we deliver cutting-edge solutions that drive growth and set industry standards.

.png)

2 in 1 Fiber Laser Cutting Machine

(H Beam + Sheet)

The 2-in-1 H-beam and sheet fiber laser is an innovative and efficient solution for cutting both H-beams (structural beams) and flat metal sheets. Using advanced fiber laser technology, this machine provides high precision and fast cutting speeds for a variety of metals. Its integrated design combines two cutting functions into a single system, reducing the need for multiple machines, saving valuable space, and lowering operational costs. Ideal for industries such as construction, manufacturing, and metal fabrication, this versatile machine enhances productivity while ensuring top-quality results on every cut.

H-Beam Cutting

-

The H-beam cutting function is used to cut through larger, thicker sections of metal that are typically used in construction, structural engineering, and other heavy-duty industries. These beams are often made of steel and are shaped like an "H," providing strength and stability for various projects.

-

The machine is typically equipped with a rotating or adjustable cutting head to handle the unique shape of H-beams.

Advantages of 2-in-1 Systems

-

Space-saving: Combining two functions into one machine saves space in the workshop.

-

Cost-effective: Since both types of cutting can be performed by a single machine, it eliminates the need for multiple machines, reducing initial investment and operational costs.

-

Increased productivity: Switching between sheet cutting and H-beam cutting without changing machines boosts workflow efficiency.

-

Precision: Fiber laser systems offer excellent precision, reducing material waste and improving the overall quality of the cuts.

-

The machine is typically equipped with a rotating or adjustable cutting head to handle the unique shape of H-beams.

Fiber Laser Technology

-

Fiber lasers are known for their high precision, speed, and efficiency in cutting metals. Unlike traditional CO2 lasers, fiber lasers use a different type of laser medium, offering faster cutting speeds and lower operational costs.

-

Fiber lasers are ideal for high-precision cutting of metals, providing cleaner edges and better cutting quality.

Sheet Cutting Capabilities

-

The sheet cutting function allows the laser to cut through flat metal sheets, such as stainless steel, aluminum, and carbon steel. This is common in manufacturing processes where precise cuts are required for components that will later be assembled into products.

Stand-Alone Pipe Cutting Machine

At SG Laser, we specialize in providing Versatile, Durable, and Precise Top of the line engineering.

Experience superior cutting performance with our state-of-the-art stand-alone pipe cutting machine, designed for a variety of materials and pipe sizes. At any time, our machines always ensure steady, clean and accurate result.

Durability & Low Maintenance

-

Designed for long-term use, the machine’s rugged build ensures that it can withstand even the harshest work environments. Built with high-quality materials and components, it’s engineered for durability and reliability.

-

Heavy-Duty Construction: Made from industrial-grade materials to withstand wear and tear over time.

-

Easy Maintenance Access: Components are easily accessible for routine maintenance, reducing downtime and extending machine lifespan.

Powerful Motor & Drive System

-

The cutting process is driven by a robust motor that can handle tough materials and thick pipes. Choose from hydraulic, pneumatic, or electric-powered options, all designed to provide high cutting speeds and power efficiency.

Safety Features

-

The safety of operators is a top priority. The stand-alone pipe cutting machine includes several built-in safety mechanisms to minimize the risk of injury or accidents.

-

Protective Shields and Guards: These safety features protect operators from sparks, debris, and rotating cutting blades.

-

Emergency Stop Button: An easily accessible emergency stop button halts machine operation instantly in case of a malfunction or emergency.

-

Safety Compliance: Meets industry standards for machine safety, ensuring peace of mind while operating.

Efficiency and Speed

-

Our pipe cutting machine is designed for accuracy and smooth results. Equipped with advanced cutting mechanisms such as circular saws, band saws, or abrasive wheels, it ensures a clean, precise cut every time, regardless of material type. This reduces the need for post-cutting work like grinding and deburring, saving both time and effort.

-

Accuracy Tolerance: Achieves tight tolerances, ensuring the cut length and angles are consistently perfect.

-

Smooth Finishes: Capable of producing smooth, sharp edges that require minimal finishing.

Automated Functionality & Programmable Controls

-

For maximum productivity, the machine features an automated feeding system that reduces the need for manual intervention. Simply input the desired cut parameters, and the machine will automatically feed and cut the pipe to the specified length.

-

Programmable Settings: Store cutting preferences, pipe sizes, and material types to automate the process.

-

Increased Efficiency: Reduces manual labor and improves workflow, making it ideal for high-volume applications.

Versatile Pipe Size Compatibility

-

The machine’s adjustable design accommodates a wide range of pipe diameters—from small pipes (less than 1 inch) to large industrial tubes (up to 12+ inches in diameter). Whether you're working with residential plumbing or large-scale industrial applications, the machine adapts to your needs.

-

Adjustable Clamps: Easily adjust the clamps to securely hold pipes of varying sizes, providing stability during cutting.

High-Precision Cutting

Environmentally Friendly

.png)

De-rust fiber laser machine

SG Laser offers advanced de-rust fiber laser machine that is capable of efficiently removing rust, corrosion, and surface contaminants from metal surfaces. This technology uses high-powered fiber lasers to target and break down rust and other impurities, effectively restoring metal surfaces to their original condition. Unlike traditional cleaning methods that rely on abrasive materials or chemicals, laser rust removal is a non-contact, eco-friendly process that minimizes the risk of damaging the underlying metal.

The process works by focusing concentrated laser energy onto the contaminated area, which causes the rust and corrosion to vaporize or be blown away by the force of the laser pulses. This results in a clean and smooth metal surface without affecting the integrity or structure of the material. Fiber laser de-rusting machines are ideal for industries such as automotive, aerospace, shipbuilding, and manufacturing, where maintaining metal components in pristine condition is crucial.

Laser Beam and Focused Energy

-

The fiber laser emits a focused beam of light that delivers high-energy pulses to the rusted metal surface.

-

The intense energy from the laser heats the rust or corrosion on the metal, causing it to evaporate or be blown off the surface.

-

The process is non-abrasive, meaning it doesn't damage the underlying metal, and the laser can be precisely controlled to target the rust without affecting the surrounding areas.

Minimal Heat Affected Zone (HAZ)

-

Since the fiber laser can be focused on a small area with high precision, it generates a very narrow heat-affected zone (HAZ). This reduces the risk of warping or damaging the underlying metal, making the process particularly useful for thin-walled or delicate materials.

No Chemicals or Abrasives

-

Unlike traditional rust removal methods (such as sandblasting or using chemical rust removers), laser rust removal doesn't require the use of any harsh chemicals or abrasive materials. This makes the process environmentally friendly and reduces the need for hazardous waste disposal.

-

It also eliminates the risk of contamination or secondary rusting that can occur with other methods.

-

The process doesn't require the use of chemicals, abrasives, or harsh cleaning agents, making it an environmentally friendly alternative to traditional rust removal methods. It also reduces the risk of creating harmful waste products.

Fiber Laser Source

-

The fiber laser used in these machines is a high-power laser that uses optical fibers to generate a laser beam. The laser source typically has a wavelength of around 1.064 microns, which is highly effective for welding metals, particularly those with high reflectivity like copper and aluminum.

-

The laser beam is tightly focused, allowing for high precision and fine control over the welding process.

Welding Process & Capabilities

-

Laser welding involves the use of a focused laser beam to melt the base materials and form a strong joint. The laser's heat causes the material at the weld joint to melt and fuse together, forming a strong bond when cooled.

-

Fiber laser welding is known for its precision, enabling users to weld in very small or hard-to-reach areas, unlike traditional welding methods (e.g., MIG or TIG welding).

High Precision and Control

-

The ability to focus the laser to a very small point allows for extremely fine, high-precision welding. This makes fiber laser welding ideal for delicate tasks such as welding thin sheets, small components, or intricate designs.

-

The welding depth, heat input, and width can be precisely controlled by adjusting the parameters of the laser, such as power, speed, and pulse duration.

-

Metals: Fiber laser welding works on a wide range of metals, including stainless steel, aluminum, titanium, copper and various alloys.

-

It is particularly effective on thin sheet metals, and it can be used for welding components in industries like electronics, automotive, aerospace, and medical devices.

Welding Positions

-

Fiber laser welding machines can be used in various positions, including flat, vertical, and overhead, depending on the setup and the material being welded.

-

Flexible robotic arms or handheld welding systems can be integrated with fiber laser machines to further enhance versatility.

Advantages of Fiber Laser Welding

-

High Precision: Fiber laser welding allows for small, precise welds, making it ideal for applications where minimal distortion and high-quality results are essential.

-

Speed: It can achieve high welding speeds, leading to improved productivity and shorter production cycles.

-

Minimal Heat Affected Zone (HAZ): Because the fiber laser focuses the heat on a very small area, it minimizes the heat-affected zone, reducing the risk of distortion or damage to surrounding areas.

-

Clean Welds: Fiber lasers produce cleaner, higher-quality welds with less spatter and oxidation, reducing the need for post-welding cleaning.

-

No Contact Welding: Since the fiber laser beam doesn’t physically touch the workpiece, there is no wear on the welding tool, and no need for filler material in many cases.

-

Automation: Fiber laser welding is compatible with automated systems, which can further enhance the efficiency and repeatability of the welding process, especially in mass production settings.

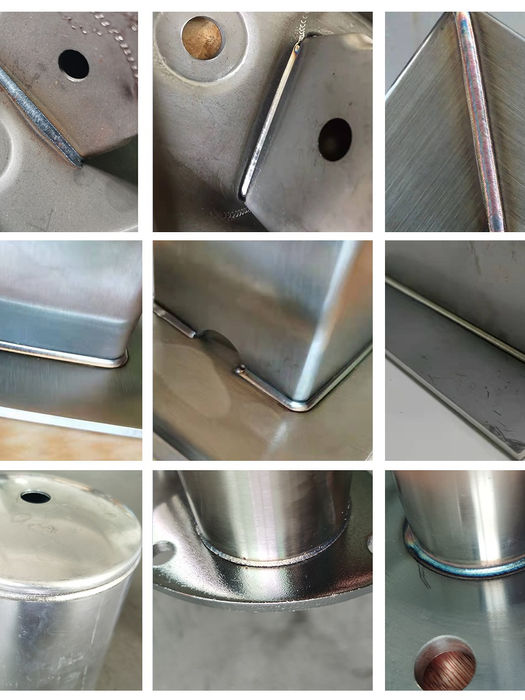

SG Laser's fiber laser welding machine uses advanced fiber laser technology to create high-precision welds with exceptional speed and control. This machine is widely used in industries such as manufacturing, automotive, aerospace, and metalworking, where clean, strong, and precise welds are required. Compared to traditional welding methods, fiber laser welding offers faster processing times, reduced heat-affected zones, and minimal distortion. It is ideal for welding thin sheets, delicate components, and intricate joints, providing superior weld quality with a smooth, consistent finish. The machine is also low-maintenance, energy-efficient, and capable of welding a variety of materials, including stainless steel, aluminum, and titanium.

Material Compatability

Fiber Laser Welding Machine

Cleaning Capability & Speed

-

Laser rust removal is typically faster than other traditional methods. Since the laser can cover large areas quickly and precisely, it can significantly reduce cleaning time compared to manual scraping or chemical cleaning.

-

The laser leaves clean surfaces, which typically don't require much post-processing. This can reduce labor and time spent on additional cleaning or surface treatments.

-

Fiber laser systems offer precise control over the cleaning process, allowing users to selectively remove rust without damaging the underlying metal or surface.

.png)